In industries where extreme temperatures are part of everyday operations-steelmaking, ceramics, petrochemicals, power generation-choosing the right insulation material is critical. Ceramic fiber insulation has become a go-to solution for high-temperature environments due to its exceptional thermal resistance, low weight, and versatility.

Whether you're an engineer, plant manager, or industrial designer, understanding ceramic fiber insulation can help you improve energy efficiency, reduce downtime, and extend equipment life. This guide covers everything you need to know-from properties and types to applications and benefits.

What Is Ceramic Fiber Insulation?

Ceramic fiber insulation, sometimes referred to as alumino-silicate fiber, is made from high-purity raw materials like alumina (Al₂O₃) and silica (SiO₂). It's manufactured by melting these materials at high temperatures and spinning or blowing them into fine fibers, which are then formed into various shapes such as blankets, boards, papers, and modules.

The result is a lightweight, non-combustible material capable of withstanding temperatures ranging from 1260°C to over 1430°C , depending on the product grade.

Key Benefits of Ceramic Fiber Insulation

High Thermal Resistance: Designed to perform in extreme heat, ceramic fiber is suitable for direct contact with flames or high-temperature gases.

Low Thermal Conductivity: Excellent insulation performance means less heat loss and lower energy costs.

Lightweight and Easy to Handle: Significantly lighter than firebrick or castable materials, making installation faster and safer.

Chemical Stability: Resistant to most chemicals, including acids and alkalis, except hydrofluoric and phosphoric acids.

Shock Resistance: Withstands rapid temperature changes without cracking or breaking.

Fireproof and Non-Toxic: Provides passive fire protection and is environmentally safe when properly handled.

Types of Ceramic Fiber Insulation Products

1.Lukewool Ceramic Fiber Blanket

Flexible, needled fiber mat without binders.

Ideal for lining kilns, furnaces, and thermal reactors.

Thickness: 6mm – 50mm | Density: 64–160 kg/m³

2. Lukewool Ceramic Fiber Board

Rigid insulation board for structural strength.

Used for back-up insulation and lining industrial equipment.

Available in standard and high-density grades.

3. Lukewool Ceramic Fiber Paper

Thin, flexible sheets made of alumina-silica fibers.

Used for gasket, sealing, or heat shielding applications.

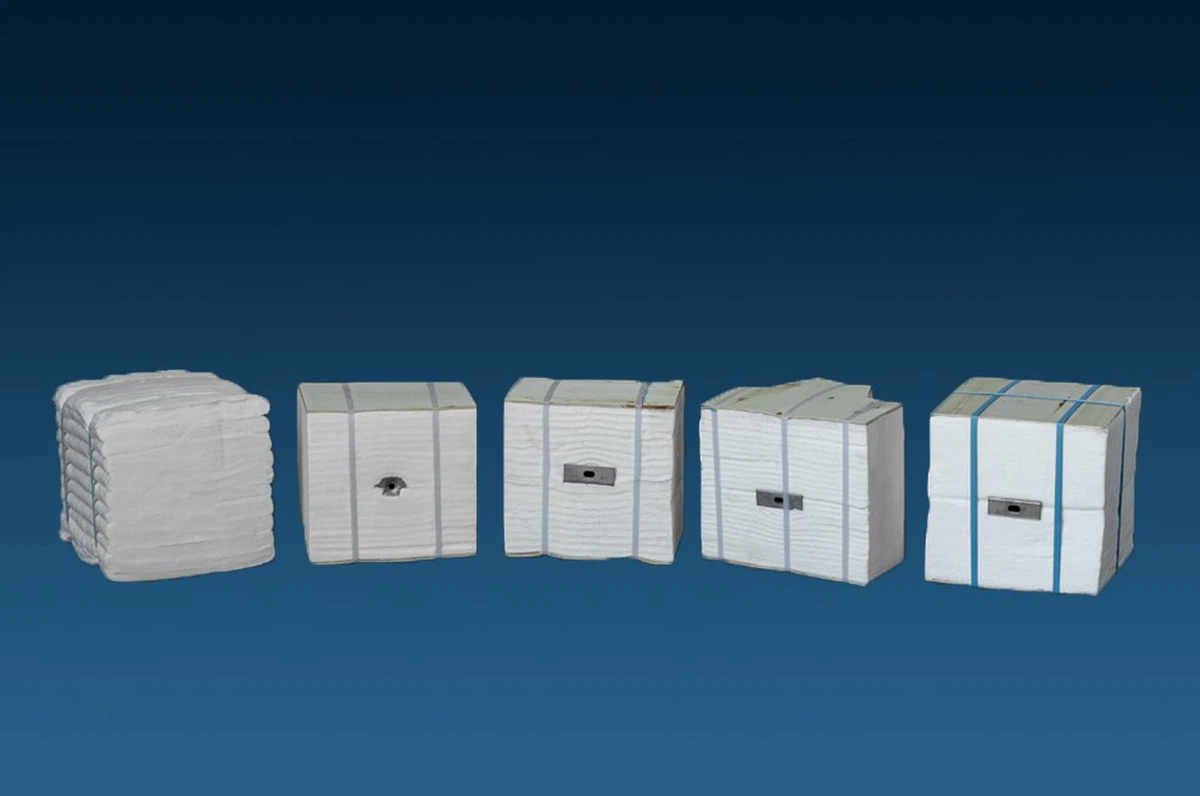

4. Lukewool Ceramic Fiber Modules

Pre-folded or stacked blanket modules for fast furnace lining.

Speed up installation, reduce heat loss, and improve insulation uniformity.

Common Applications Across Industries

| Industry | Application |

|---|---|

| 🔩 Metallurgy | Furnace linings, ladle insulation, tundish covers |

| 🧱 Ceramics | Kiln insulation, door seals, firing zones |

| 🧪 Petrochemical | Reformer linings, pipe insulation, flare stacks |

| 🔥 Power Generation | Boiler insulation, turbine enclosures |

| 🚀 Aerospace & Defense | Heat shields, engine compartments, fireproof barriers |

| 🏗️ Construction | Fire barriers, oven insulation, passive fire protection |

Ceramic fiber insulation is a powerful tool in any high-temperature engineering arsenal. Its unique properties-lightweight, high heat resistance, chemical stability, and easy installation-make it an ideal choice for a wide range of industries. By choosing the right product and supplier, you ensure better performance, lower energy costs, and safer operations.

Why Choose Ceramic Fiber from Luke New Material?

At Luke New Material, we provide high-purity ceramic fiber insulation with:

🏭 Over 40 years of experience in high-temperature solutions

🌍 Exported to 50+ countries worldwide

✅ ISO-certified manufacturing with strict quality control

📦 Custom OEM, packaging, and sizing available

🌱 Energy-saving & eco-friendly options

👉 Get a Quote Today or Talk to Our Experts

📧 international@lukewool.com | 🌐 www.lukewool.com